Geotextile membranes are a versatile type of fabric designed to provide protection and support when placed within the ground. They function as a barrier that can separate materials, prevent erosion, and improve drainage in various applications. Often referred to as "Terram" (a well-known brand specializing in geotextile membranes), these membranes are widely used in construction, landscaping, and civil engineering projects. Think of them as a specialized textile that acts like an underlayer to enhance the stability and functionality of the surface above it.  The most common application for geotextile membranes lies in drainage projects, such as land drains and soakaways. These membranes are typically used to line soakaway pits or surround perforated drainage pipes to prevent silt or debris from entering and blocking the system. By ensuring the integrity of the drainage structure, they help extend its lifespan. For instance, in French drain setups, the membrane wraps around the pipe to allow water to pass through while stopping larger particles from clogging the system. Geotextile membranes excel in filtration mechanisms, enabling them to separate debris or large particles from water while still allowing liquid to flow freely. This capability is crucial in preventing issues like flooding and maintaining smooth water movement. The "needle-punched" nature of permeable membranes creates tiny holes that filter out larger particles while permitting the passage of smaller ones. This filtration process can also encourage lateral water flow, dissipating the kinetic energy of rising groundwater and redirecting it laterally, thus minimizing the risk of flooding. In horse arenas, a thick, heavy-duty non-woven membrane is essential, with a minimum thickness of 300 GSM, though 500 GSM is recommended. This membrane is installed between the sand surface and the sub-layer to prevent sand from mixing with the aggregate below. Given the heavy foot traffic in arenas, the membrane needs to withstand significant pressure without compromising its structural integrity. Geotextile membranes play a vital role in separating different types of soil and aggregates to prevent their intermixing, particularly in areas where water flows through. Mixing different soil types can lead to uneven surfaces and subsidence, as finer particles may wash away during rainfall. Geotextile membranes effectively stop smaller particles from being displaced, even in wet conditions. This prevents drainage channels in coarser soils from becoming clogged, reducing the risk of standing water and flooding after rain. Practical examples include using membranes between sand and gravel on driveways to keep the gravel from sinking into the sand, or between type 1 MOT and a sand layer to prevent sand from seeping into the hardcore below. Specialized geotextile membranes are frequently employed in coastal regions to combat erosion. These membranes need to be strong enough to resist damage from coastal defense structures, yet permeable enough to allow water to drain effectively. For instance, membranes used alongside gabions require exceptional strength and permeability to maintain their effectiveness while allowing proper drainage. Weed control fabrics, another form of geotextile membrane, serve to inhibit weed growth while promoting the healthy development of desired plants. By limiting weed competition for nutrients and space, these membranes ensure that cultivated plants receive the resources they need to thrive. Additionally, they can act as barriers to contain harmful substances, such as those found at landfill sites, preventing contamination of surrounding areas. Ground reinforcement membranes are extensively utilized in construction, drainage, and engineering projects. Woven geotextiles, for example, are ideal for stabilizing embankments and roads built on unstable soils. Their high strength enables the creation of steeper slopes and provides enhanced ground stabilization. Cross-hatch membranes, often referred to as biaxial geogrids, are particularly effective in retaining the shape of ditches and drains, ensuring long-term structural integrity. Geotextile membranes come in various forms, each tailored to specific applications. They are generally categorized as permeable or impermeable. These membranes allow water to pass through tiny holes, offering both woven and non-woven options. Each type has unique benefits and limitations. Woven permeable membranes are crafted by interweaving individual strands, creating a cohesive membrane. While less porous than non-woven membranes, they possess high load-bearing capacity and are suitable for erosion control and reinforcement projects. They're also more budget-friendly, making them ideal for use under patios or asphalt. Conversely, non-woven membranes are formed by bonding synthetic fibers and punching holes into the material, enhancing their drainage capabilities. Non-woven membranes are commonly used in French drains and soakaway crates. Although the term "Terram" is often associated with non-woven membranes, it's simply a brand name, and similar products are available from other manufacturers. Impermeable membranes completely block water flow, making them suitable for projects requiring water containment or exclusion. Examples include attenuation tank systems where water must be retained within a defined area. Installing geotextile membranes is a straightforward process involving a few key steps. The exact method depends on the specific project requirements. For a comprehensive guide, check out our blog post titled "5 Tips for Laying Geotextile Membrane Flawlessly." Author Bio Nathan has over 12 years of experience in the drainage and plastics industry. With a background in both builders' merchants and major manufacturers, he brings extensive industry and product knowledge to his role at EasyMerchant, where he focuses on streamlining processes for tradespeople. Terram T1000 Non Woven Geotextile Membrane – Custom Size

The Floor Springs with Speed Adjustment Valves with 130-0 degree and 130-20 degree double closing speed adjustment valves is made in 304 Stainless Steel to ensure durability. Latching and closing speeds can be easily adjusted to ensure safety. The Speed Adjust Floor Springs are suitable for maximum 1500 wide door leaf and the maximum bearing weight is 130kgs. The opening maximum of the door leaf is 105 Degree, can be located at 90 degree or 105 degree.

Floor Spring Door,Glass Door Floor Spring Price,Aluminium Door Floor Spring,Floor Spring Door Fitting Leader Hardware Manufacturer Limited , https://www.leaderhardwarecn.comWhat Are Geotextile Membranes?

Different Uses for Geotextile Membranes

Drainage Geotextile Membranes

Filtering Debris From Drains

Horse Arenas

Separating Types of Aggregates

Protecting Against Erosion

Weed Membranes

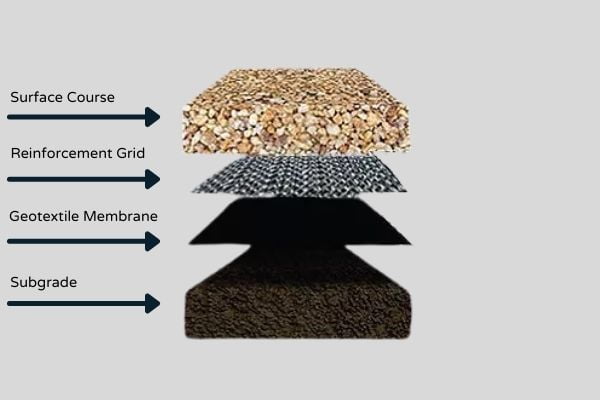

Reinforcement in Construction, Drainage and Engineering Projects

Types of Geotextile Membrane

Permeable Geotextile Membranes

Impermeable Geotextile Membranes

How To Install A Geotextile Membrane

Nathan Wilde

Shop Geotextile Membranes:

Sale!

(82)

From £15.54 Excl. VAT

Select options